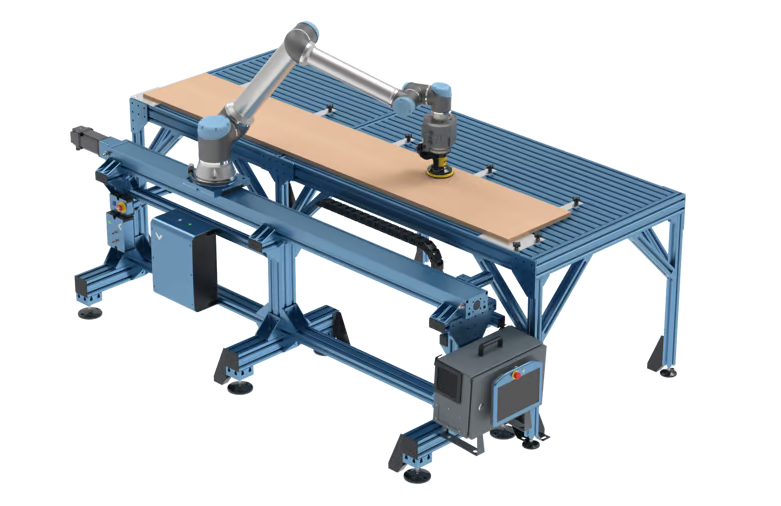

We are experts in using the latest generation of collaborative robot technology to drive down process costs and develop new capabilities across a wide range of industry applications.

Based in Dundee, our small but diverse team brings together expertise in robotics, computer vision, data science, and engineering. We provide the full spectrum of robotics design, supply, integration and support.

We offer a

free automation audit

to help you identify opportunities to make your operations more cost-effective using robotic automation.

Why Automate?

Robotics systems provide advantages across the board

Throughput

24h operation combined with faster cycle times results in a significant throughput increase.

Traceability

Robotic systems offer improved traceability helping you identify errors quickly and efficiently.

Cost

Payback time can be as little as 6 months given the OpEx savings and cycle time reduction.

Labour

Keep your manual workforce where they’re needed most by automating repetitive tasks.

Scalability

Robotics systems can be scaled predictably to meet your growing needs.

Adaptable

Robotics systems are inherently adaptable to process changes without major modification.

Safety

The latest generation of collaborative robots avoid collisions using an array of smart sensing technology.

Data

More data, more control. Robotic systems collect process data to enable targeted improvements.

Quality

With sub-millimetre robotic precision, you can ensure a high-quality repeatable process.

Explore

our diverse range of Cobot applications, catering to an array of industries such as manufacturing and logistics. Our cutting-edge solutions are tailored to enhance productivity and safety.

Experience the ease of automation and efficiency optimization with our intuitive technology.

Working together.

Analyse

We work with you to develop a comprehensive analysis of the intended application, and define an intelligent automation strategy and roadmap.

Develop

Development of a first of a kind bespoke automation solution designed and optimised to your requirements.

Deploy

System roll-out and scale-up to all parallel processes. This stage includes system integration, commissioning and operator training.

Support

We offer long term support including monitoring, maintenance, training & continuous improvement.

Contact

Contact us

General Enquiries

info@branchrobotics.tech